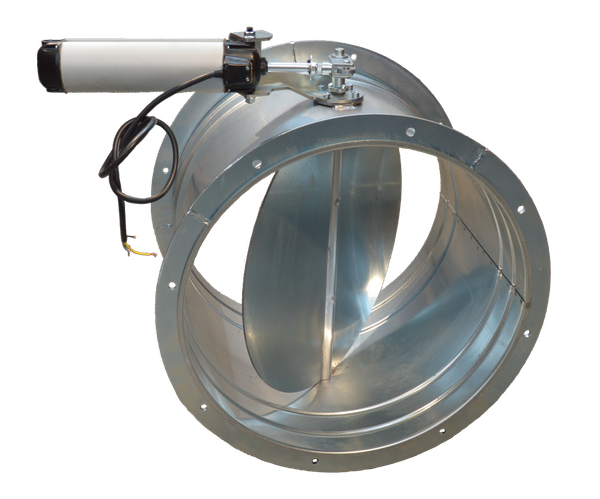

BUTTERFLY DAMPERS

Our

butterfly dampers are designed to regulate the flow of fluids within industrial pipelines. These valves are named after their characteristic shape, which resembles a butterfly, with a disc welded onto a central pin inside a pipe. Thanks to the reduced number of moving components, they are particularly efficient and reliable.

Our product lines

On Brass bearings

Butterfly dampers

on brass bearings

are designed with bronze seats where the pin rotates. Bronze is known for its durability and self-lubricating properties, reducing friction during the opening and closing of the dampers. This design aims to provide greater longevity and smoother operation over time.

On Bearings

Butterfly dampers

on bearings use ball bearings to enable smoother rotation of the valve diaphragm. This configuration aims to optimise operational efficiency by reducing friction and allowing quieter movement. Bearings offer greater precision and are ideal for applications requiring frequent or precise flow adjustments. The bearing solution is often chosen for environments where maintaining efficient operation is important.

Discover the differences between our

butterfly dampers

Find the line that perfectly fits your needs.

| On Brass bearings | On Bearings | |

|---|---|---|

| Available diameters | Ø80 ÷ Ø500 | Ø80 ÷ Ø1000 |

| Maximum depression | 500 mmH20 | 500 mmH20 |

| Standard drives | Spring, Manual, Electric Linear, Electric Rotary, Pneumatic Linear, Pneumatic Rotary | Manual, Electric Linear, Electric Rotary, Pneumatic Linear, Pneumatic Rotary |

| On-demand drives | Electro-Pneumatic | Electro-Pneumatic |

| Rotation | On brass bearings | On bearings |

Didn't find what you're looking for?

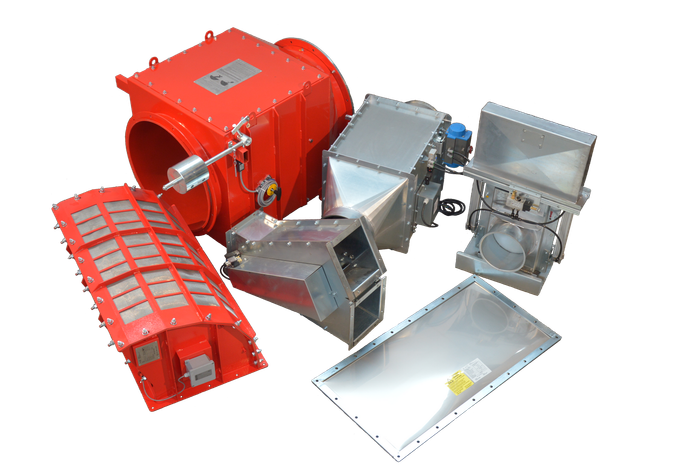

Discover our line of products for plant safety in case of explosions or flames

If you haven't found what you're looking for yet, don't hesitate to contact us!!

Headquarters

Opening hours

- Mon - Fri

- - -

- Sat - Sun

- Closed